Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

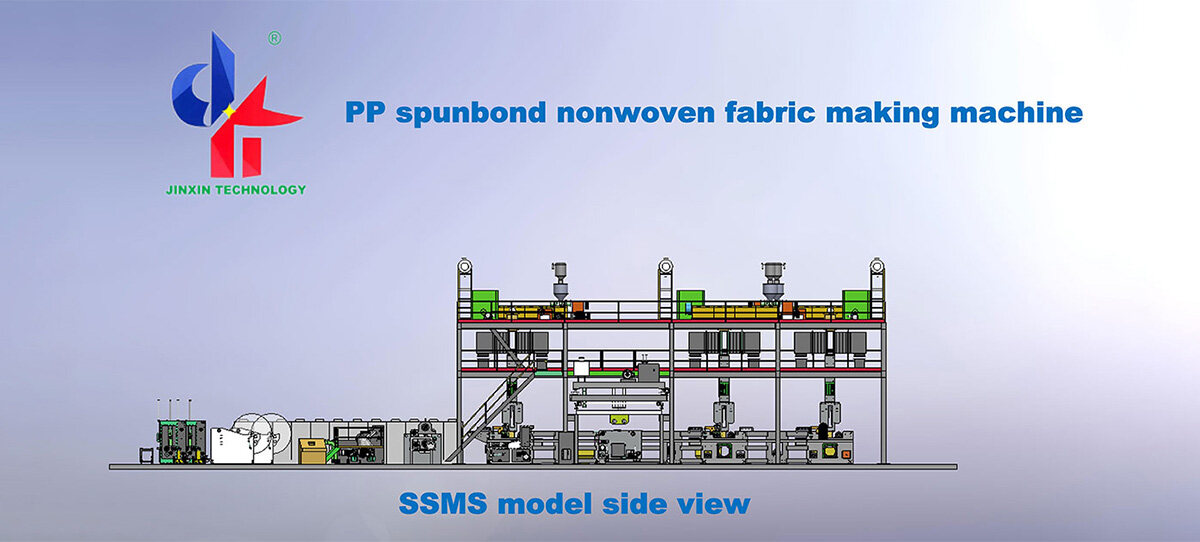

2400mm SSMS type nonwoven equipment

Our factory's SSMS PP spunbond nonwoven production line sets itself apart from other vendors in the same sector because to its exceptional quality. The non-woven fabric created by our spunbond production line, in contrast, has a softer texture and a more equal weight distribution, making it ideal for premium medical products like diapers, masks, and isolation apparel.

| Model | JX-SSMS |

|---|---|

| Product Width | 2400mm |

| Equipment Size | 50*18*12m |

| Mechanical Speed | 450m/min |

| Gram Weight | 10-120g/m2 |

| Daily Output | 16-24T/Day |

| Transformer Capacity | ≈1350KVA |

| Power Consumption | 1200°-1650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Why combine spunbond polypropylene with melt blown polypropylene to create SSMS?

As we know spunbond polypropylene has many excellent properties, strength, and durability being just two of those. On the other hand, meltblown has relatively weak tensile properties but due to the smaller fibers and larger surface area taken up by the fibers, it has excellent wicking and barrier properties. So together, they can create a strong product that can also offer a barrier to fluids and particles.

The Advantage of Nonwoven Fabric Making Machines

1.High-accurate raw material blender for polypropylene and additives;

2.High capacity extrusion machine with good screw and barrel;

3.High-performance melt filtration system;

4.High Speed with highly accurate melt pump;

5.Lastest melt flow design and spinning system;

6.Well-know PLC control system and motors;

7.Smart operation program and monitoring system.

The SSMS PP spunbond nonwoven production line produced by our factory stands out from other suppliers in the same industry with its outstanding quality. In contrast, the non-woven fabric produced by our spunbond production line has a softer texture and a more even weight distribution, which is suitable for high-end medical materials including baby diapers, masks, and isolation clothing.

FAQ

Q1. What kinds of after-sale services you can provide for me?

A1. Because we successfully installed more than 50 sets of nonwoven fabric machines all over the world, so we have rich experiences in machine installation and training. Our after-sale service team will help your people build the machine, and install the machine step by step. We will provide complete machine installation drawings for you.

Q2. What is the warranty and guarantee term of your company?

A2. 12 months after the machine finished installation

Q3. Can we choose different brands of parts? can we customize the machine according to our needs?

A3. Yes, our equipment is customized and can be designed according to your requirements.

Q4. How long does it take to produce the machine?

A4. As we have different types of nonwoven fabric machines, such as S/SS/SSS/SMS/SMMS production line, so the delivery time is different. normally, the delivery time is 3-6 months after confirming payment.